08 May, 2017 (Shanghai, China) – ABB shaft generators will raise the energy efficiency on two DFDS vessels which have been designed to meet the latest environmental regulations. Two shaft generators will be installed in each of the cargo Ro-Ro ships allowing the main engines to operate at a wider, more optimal speed range.

DFDS VesselThe shaft generator system takes its power from main engines, thereby increasing safety if there is a failure on the auxiliary engine. The ships’ main engines will also be turbocharged by ABB’s latest generation technology.

Juha Koskela, Managing Director of ABB’s Marine and Ports business said, “Efficiency and safety are cornerstones of the maritime industry and our shaft generators will introduce both to these DFDS vessels. Not only is this an environmentally friendly technology but it is also very cost effective.”

By using an alternative power source the shaft generators allow the main engines and the propeller pitch to be optimized no matter what the vessel speed, adding the load on the main engine and improving overall fuel efficiency. The system will be tailored for the vessels which will operate in DFDS’ North Sea network.

The shaft generator system also enables the vessel to be sensitive to the local community and environment when it reaches port as it is compatible with shore-to-ship power. This allows the ship to shut down its auxiliary engines when it berths, therefore reducing emissions and vibrations.

Two high performance A270-L turbochargers, for two-stroke engines were selected for each vessel, reducing fuel and consequently lowering emissions further. For the typical demands of low-speed marine engines, the turbochargers offer greater engine operating flexibility: high pressure tuning for part or low loads, and designed for best efficiency in slow-, and ultra-slow steaming.

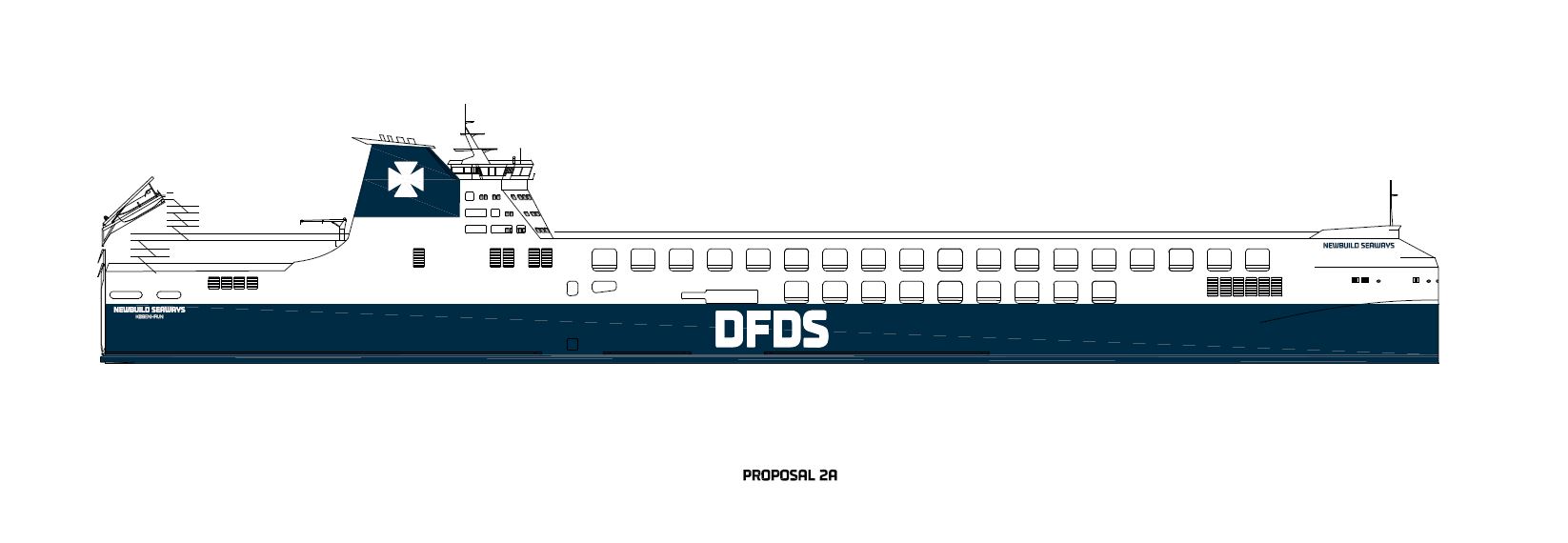

The two 6,700 lane meter Ro-Ro’s, the largest ever freight vessels to be built for DFDS, will be built by Jinling Shipyard in China for delivery at the beginning of 2019, with an option of a further four vessels.

About ABB

ABB (ABBN: SIX Swiss Ex) is a pioneering technology leader in electrification products, robotics and motion, industrial automation and power grids, serving customers in utilities, industry and transport & infrastructure globally. Continuing more than a 125-year history of innovation, ABB today is writing the future of industrial digitalization and driving the Energy and Fourth Industrial Revolutions. ABB operates in more than 100 countries with about 135,000 employees. www.abb.com

ABB轴带发电机和涡轮增压器助力环保型货船提高能效

ABB技术将在降低滚装船海上及港口排放方面发挥关键作用

2017年5月8日,中国上海——丹麦联合汽船有限公司(DFDS) 选择ABB 轴带发电机以大幅提升两艘滚装船的能效,确保设计符合最新环保法规。每艘滚装船都将安装两台轴带发电机,使主机能在更宽、更优化的速度范围内运行。该轴带发电机系统从主机获取动力,从而提高辅机故障时的船舶安全性。ABB最新的发电技术还为船舶主机提供涡轮增压。

ABB船舶与港口业务单元全球负责人寇跃华(Juha Koskela)说,“效率和安全是船舶行业的基石,我们的轴带发电机使得这两艘DFDS滚装船能够兼顾二者,这不仅仅是一种环保技术,而且还极具成本效益。”

由于采用了可选动力源,轴带发电机可以同时使螺旋桨螺距和主机在优化点工作,不受航速限制,从而增加主机负荷,提高总体燃油效率。该系统将针对船只在英国和荷兰之间营运情况而量身定制。

由于可兼顾岸基供电,轴带发电机系统还能在泊岸时关闭辅机,减少排放和振动,从而起到保护当地社区和环境的积极作用。

每艘滚装货船都选配了两台二冲程低速机用的 A270-L型 涡轮增压器,从而降低油耗,减少排放。针对低速机特定的实际需求,该系列涡轮增压器能够帮助发动机增强运行灵活性:高增压调节技术可以优化发动机在部分或低负荷运行时的性能,而在船舶慢速或超慢速航行时实现卓越效率。

这两艘6, 700延米滚装船是有史以来为DFDS建造的最大货船,由中国金陵船厂建造,将于2018年初交付,后续可追加4艘。

关于ABB

ABB(ABBN: SIX Swiss Ex)是全球电气产品、机器人及运动控制、工业自动化和电网领域的技术领导企业,致力于帮助电力、工业、交通和基础设施等行业客户提高业绩。基于超过125年的创新历史,ABB正在不断地推动能源革命和第四次工业革命,谱写行业数字化的未来。ABB集团业务遍布全球100多个国家,雇员达13.2万。ABB在中国拥有研发、制造、销售和工程服务等全方位的业务活动,40家本地企业,1.7万名员工遍布于139个城市,线上和线下渠道覆盖全国300多个城市。

www.abb.com

For more information please contact:

Media Relations

Phone: +47 409 04 294

Email: peter.lovegrove@no.abb.com