01 May 2025 – In a significant milestone for the company, Thordon Bearings has seen its RiverTough tailshaft bearing solution surpass 500 installations in the workboat sector.

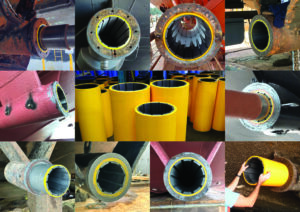

Primarily a retrofit solution but also increasingly specified for newbuilds, RiverTough is designed for coastal and inland waterways, where conditions are typically muddy and abrasive. The solution, applied in combination with hard-coated nickel-chrome-boron (NiCrB) Thordon shaft sleeves, has been verified as outlasting rubber bearings by a factor of two or more in the harshest operating environments. Workboat operators serving the Mississippi River, U.S.A., have reported wear rates of just 0.07–0.1 mm (0.003–0.004 inches) over 6,000–7,000 hours of annual use.

RiverTough’s unparalleled resilience cuts maintenance and yields significant cost savings over the vessel lifecycle, in a benefit that resonates with owners of tow- and tugboats worldwide. Uptake has been particularly strong in the U.S.A., where two strategically located warehouses – in New Orleans (LA), and Paducah (KY) – have facilitated over 400 installations to date. Accounting for over 60 more, South America is another strong market for RiverTough.

As well as lasting longer, RiverTough is easier to machine, install, and align than rubber bearings. Its length-to-diameter (L/D) ratio of 3:1 results in superior water flow and reduced edge loading when compared with the 4:1 L/D ratio of rubber bearings.

“This is a notable milestone for RiverTough tailshaft bearings, and for Thordon, and part of a growing market acknowledgement that using RiverTough tailshaft bearings leads to reduced maintenance requirements, allowing owners to keep boats working longer, moving their cargo with less downtime,” said Jason Perry, Thordon’s Regional Manager, North America. “We are responding to customer needs, and that has allowed us to continue Thordonizing the workboat fleet, by growing RiverTough and NiCrB Thordon shaft sleeve numbers but also by serving increasing demand for durable TG100 mechanical shaft seals, ThorPlas-Blue and SXL rudder bearings, Thordon pucker seals, and ThorPlas-Blue steering linkage bearings.”

About Thordon Bearings

Thordon Bearings designs and manufactures a complete range of journal bearing and seal systems for application across a number of sectors, including marine, offshore, clean power generation, mining and other pump and land-based industrial sectors. Thordon Bearings’ polymer bearing solutions offer excellent wear life, reduced noise and low operating friction while providing a dependable, long-lasting, environmentally friendly alternative to grease and oil-lubricated bearings. Thordon systems and bearings are available worldwide through over 70 agents and distributors.